Introduction to Oxides: Building Blocks of Nature and Innovation

Oxides– compounds developed by the reaction of oxygen with various other components– stand for one of one of the most diverse and vital courses of materials in both natural systems and engineered applications. Found perfectly in the Planet’s crust, oxides work as the foundation for minerals, ceramics, steels, and progressed digital elements. Their properties differ commonly, from shielding to superconducting, magnetic to catalytic, making them important in fields varying from power storage space to aerospace design. As material science pushes limits, oxides are at the center of technology, enabling technologies that define our contemporary world.

(Oxides)

Architectural Variety and Functional Properties of Oxides

Oxides display an extraordinary series of crystal frameworks, consisting of simple binary forms like alumina (Al ₂ O FIVE) and silica (SiO TWO), intricate perovskites such as barium titanate (BaTiO ₃), and spinel structures like magnesium aluminate (MgAl two O FOUR). These structural variations give rise to a vast range of functional behaviors, from high thermal stability and mechanical hardness to ferroelectricity, piezoelectricity, and ionic conductivity. Understanding and tailoring oxide structures at the atomic level has actually ended up being a keystone of materials engineering, unlocking brand-new capacities in electronic devices, photonics, and quantum devices.

Oxides in Power Technologies: Storage, Conversion, and Sustainability

In the international shift towards tidy power, oxides play a main duty in battery innovation, gas cells, photovoltaics, and hydrogen manufacturing. Lithium-ion batteries rely on layered transition steel oxides like LiCoO ₂ and LiNiO two for their high energy density and relatively easy to fix intercalation behavior. Solid oxide gas cells (SOFCs) utilize yttria-stabilized zirconia (YSZ) as an oxygen ion conductor to allow reliable energy conversion without combustion. On the other hand, oxide-based photocatalysts such as TiO ₂ and BiVO four are being optimized for solar-driven water splitting, using an appealing course toward lasting hydrogen economic situations.

Electronic and Optical Applications of Oxide Products

Oxides have transformed the electronic devices market by enabling clear conductors, dielectrics, and semiconductors crucial for next-generation tools. Indium tin oxide (ITO) remains the criterion for transparent electrodes in display screens and touchscreens, while emerging options like aluminum-doped zinc oxide (AZO) goal to decrease dependence on scarce indium. Ferroelectric oxides like lead zirconate titanate (PZT) power actuators and memory devices, while oxide-based thin-film transistors are driving versatile and clear electronics. In optics, nonlinear optical oxides are key to laser regularity conversion, imaging, and quantum communication innovations.

Duty of Oxides in Structural and Safety Coatings

Beyond electronic devices and energy, oxides are essential in architectural and safety applications where severe problems demand extraordinary efficiency. Alumina and zirconia finishings provide wear resistance and thermal obstacle security in generator blades, engine elements, and cutting tools. Silicon dioxide and boron oxide glasses form the backbone of fiber optics and display technologies. In biomedical implants, titanium dioxide layers enhance biocompatibility and corrosion resistance. These applications highlight just how oxides not just secure materials but also expand their functional life in several of the toughest settings understood to design.

Environmental Remediation and Eco-friendly Chemistry Using Oxides

Oxides are increasingly leveraged in environmental management via catalysis, toxin removal, and carbon capture modern technologies. Metal oxides like MnO ₂, Fe Two O FOUR, and chief executive officer ₂ serve as catalysts in damaging down unstable natural substances (VOCs) and nitrogen oxides (NOₓ) in industrial emissions. Zeolitic and mesoporous oxide frameworks are checked out for CO two adsorption and splitting up, sustaining initiatives to mitigate environment modification. In water treatment, nanostructured TiO ₂ and ZnO offer photocatalytic deterioration of impurities, pesticides, and pharmaceutical deposits, demonstrating the capacity of oxides beforehand sustainable chemistry practices.

Challenges in Synthesis, Stability, and Scalability of Advanced Oxides

( Oxides)

In spite of their versatility, developing high-performance oxide materials offers considerable technical challenges. Specific control over stoichiometry, phase pureness, and microstructure is critical, especially for nanoscale or epitaxial films utilized in microelectronics. Many oxides deal with poor thermal shock resistance, brittleness, or minimal electrical conductivity unless drugged or engineered at the atomic level. In addition, scaling research laboratory breakthroughs right into industrial procedures usually requires conquering price barriers and making sure compatibility with existing manufacturing infrastructures. Dealing with these issues demands interdisciplinary partnership across chemistry, physics, and design.

Market Trends and Industrial Demand for Oxide-Based Technologies

The international market for oxide products is expanding swiftly, fueled by growth in electronics, renewable resource, protection, and medical care fields. Asia-Pacific leads in consumption, especially in China, Japan, and South Korea, where demand for semiconductors, flat-panel screens, and electric automobiles drives oxide development. The United States And Canada and Europe preserve solid R&D financial investments in oxide-based quantum products, solid-state batteries, and environment-friendly technologies. Strategic collaborations in between academic community, start-ups, and international companies are speeding up the commercialization of unique oxide solutions, reshaping industries and supply chains worldwide.

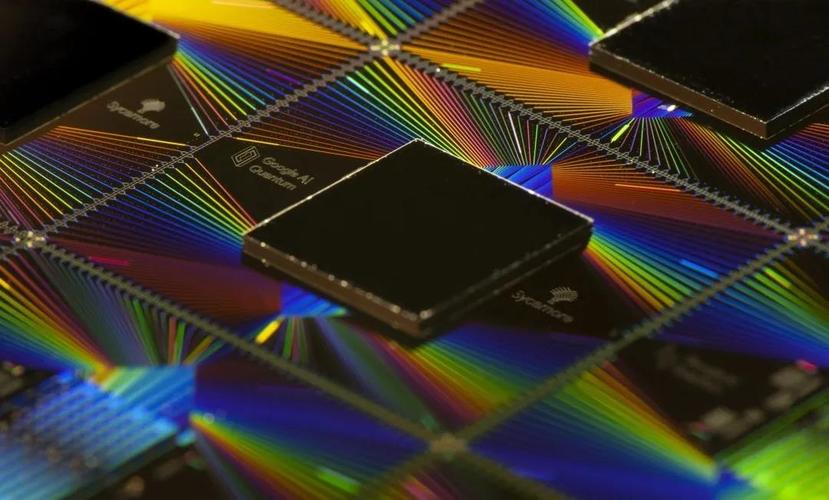

Future Prospects: Oxides in Quantum Computer, AI Hardware, and Beyond

Looking ahead, oxides are poised to be fundamental materials in the next wave of technical revolutions. Arising research study right into oxide heterostructures and two-dimensional oxide user interfaces is revealing exotic quantum sensations such as topological insulation and superconductivity at area temperature. These explorations could redefine computing architectures and enable ultra-efficient AI equipment. Furthermore, advances in oxide-based memristors might pave the way for neuromorphic computing systems that resemble the human brain. As scientists remain to unlock the surprise possibility of oxides, they stand prepared to power the future of smart, lasting, and high-performance innovations.

Provider

RBOSCHCO is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality chemicals and Nanomaterials. The company export to many countries, such as USA, Canada, Europe, UAE, South Africa,Tanzania,Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech Republic, Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand, Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a leading nanotechnology development manufacturer, RBOSCHCO dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for manganese iv oxide mno2, please send an email to: sales1@rboschco.com

Tags: magnesium oxide, zinc oxide, copper oxide

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us