Intro to Waterborne Calcium Stearate

Waterborne calcium stearate has become a critical material in contemporary commercial applications because of its eco-friendly account and multifunctional capabilities. Unlike conventional solvent-based additives, waterborne calcium stearate supplies a sustainable choice that satisfies growing demands for low-VOC (unpredictable natural compound) and non-toxic formulations. As regulative stress mounts on chemical use across markets, this water-based dispersion of calcium stearate is gaining grip in finishes, plastics, building and construction materials, and a lot more.

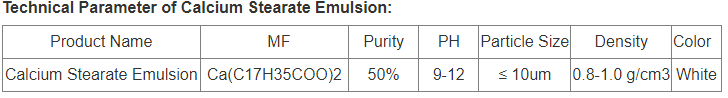

(Parameters of Calcium Stearate Emulsion)

Chemical Structure and Physical Characteristic

Calcium stearate is a calcium salt of stearic acid with the molecular formula Ca(C ‚āĀ‚āą H ‚āÉ‚āÖ O TWO)TWO. In its conventional type, it is a white, ceraceous powder recognized for its lubricating, water-repellent, and supporting residential properties. Waterborne calcium stearate refers to a colloidal diffusion of great calcium stearate fragments in an aqueous medium, usually stabilized by surfactants or dispersants to prevent pile. This solution enables easy consolidation right into water-based systems without endangering performance. Its high melting point (> 200 ¬į C), low solubility in water, and excellent compatibility with various resins make it excellent for a vast array of useful and structural duties.

Manufacturing Refine and Technological Advancements

The production of waterborne calcium stearate commonly involves reducing the effects of stearic acid with calcium hydroxide under controlled temperature and pH conditions to create calcium stearate soap, followed by diffusion in water using high-shear blending and stabilizers. Current advancements have concentrated on boosting fragment size control, enhancing solid material, and decreasing ecological influence via greener processing methods. Innovations such as ultrasonic-assisted emulsification and microfluidization are being checked out to boost diffusion security and functional efficiency, guaranteeing constant quality and scalability for commercial customers.

Applications in Coatings and Paints

In the coatings industry, waterborne calcium stearate plays a critical duty as a matting agent, anti-settling additive, and rheology modifier. It helps in reducing surface gloss while maintaining film stability, making it specifically useful in architectural paints, timber coatings, and industrial surfaces. Additionally, it improves pigment suspension and avoids sagging during application. Its hydrophobic nature also improves water resistance and toughness, contributing to longer covering life-span and minimized upkeep expenses. With the change toward water-based finishings driven by environmental regulations, waterborne calcium stearate is becoming an essential formula part.

( TRUNNANO Calcium Stearate Emulsion)

Duty in Plastics and Polymer Handling

In polymer production, waterborne calcium stearate offers largely as an inner and external lube. It promotes smooth thaw flow during extrusion and injection molding, lowering die accumulation and improving surface coating. As a stabilizer, it reduces the effects of acidic residues developed throughout PVC handling, avoiding destruction and staining. Contrasted to traditional powdered kinds, the waterborne version supplies much better dispersion within the polymer matrix, bring about enhanced mechanical properties and process effectiveness. This makes it particularly useful in stiff PVC accounts, cable televisions, and films where appearance and efficiency are extremely important.

Use in Construction and Cementitious Systems

Waterborne calcium stearate finds application in the building and construction industry as a water-repellent admixture for concrete, mortar, and plaster products. When included into cementitious systems, it develops a hydrophobic obstacle within the pore structure, significantly reducing water absorption and capillary increase. This not just boosts freeze-thaw resistance but likewise secures versus chloride access and deterioration of embedded steel reinforcements. Its simplicity of integration into ready-mix concrete and dry-mix mortars positions it as a recommended service for waterproofing in infrastructure jobs, tunnels, and below ground frameworks.

Environmental and Health Considerations

One of one of the most compelling advantages of waterborne calcium stearate is its environmental profile. Without volatile organic compounds (VOCs) and dangerous air pollutants (HAPs), it straightens with worldwide efforts to reduce commercial emissions and advertise environment-friendly chemistry. Its eco-friendly nature and low toxicity additional support its fostering in environmentally friendly product lines. However, appropriate handling and formulation are still called for to make sure employee safety and security and avoid dust generation throughout storage and transport. Life process assessments (LCAs) progressively prefer such water-based additives over their solvent-borne equivalents, strengthening their function in sustainable production.

Market Trends and Future Expectation

Driven by more stringent environmental regulation and rising consumer recognition, the market for waterborne ingredients like calcium stearate is expanding rapidly. The Asia-Pacific region, particularly, is observing solid development because of urbanization and industrialization in nations such as China and India. Key players are investing in R&D to establish tailored grades with enhanced performance, consisting of warmth resistance, faster dispersion, and compatibility with bio-based polymers. The integration of digital technologies, such as real-time surveillance and AI-driven solution tools, is expected to more maximize efficiency and cost-efficiency.

Verdict: A Sustainable Building Block for Tomorrow’s Industries

Waterborne calcium stearate represents a significant development in functional products, providing a well balanced mix of efficiency and sustainability. From coverings and polymers to building and construction and past, its adaptability is reshaping just how markets approach formulation design and procedure optimization. As firms aim to meet evolving regulatory standards and consumer expectations, waterborne calcium stearate attracts attention as a trustworthy, adaptable, and future-ready service. With recurring innovation and deeper cross-sector cooperation, it is poised to play an even greater duty in the shift towards greener and smarter manufacturing practices.

Supplier

Cabr-Concrete is a supplier under TRUNNANO of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for Concrete foaming agent, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

Tags: calcium stearate,ca stearate,calcium stearate chemical formula

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us